Sulphur Coated Urea (SCU) Plant

Coating particles or granules of urea with sulphur and a sealant result in the formation of a membrane that regulates the availability of nitrogen for plant growth. Sulphur Coated Urea (SCU) fertilizer is a slow-release fertilizer that is made by coating urea with sulphur and wax that increases nitrogen efficiency, improves plant growth and reduces water pollution, compared with water soluble fast-release urea. Sulphur Coated Urea avoid soil compaction; reduce frequency of application and reducing total cost; effectively reduce salt index, improving quality of crops; sulphur is a middle element, to provide nutrition for crops.

As a hi-tech controlled/slow-release fertilizer, Sulphur coated urea (SCU) has both effects of nitrogen and sulphur fertilizers.

ARIaNA SANAT ZAFARAN CO. SCU (Sulphur Coated Urea) Plant has an operating capacity of 240-300 tonnes per day, and their modular design allows them to be integrated together to achieve higher production capacity on demand. This modularity SCU package also allows a plant to continue production when one of the units is not operational, while also enabling rapid SCU unit start-up with lower capital investment costs.

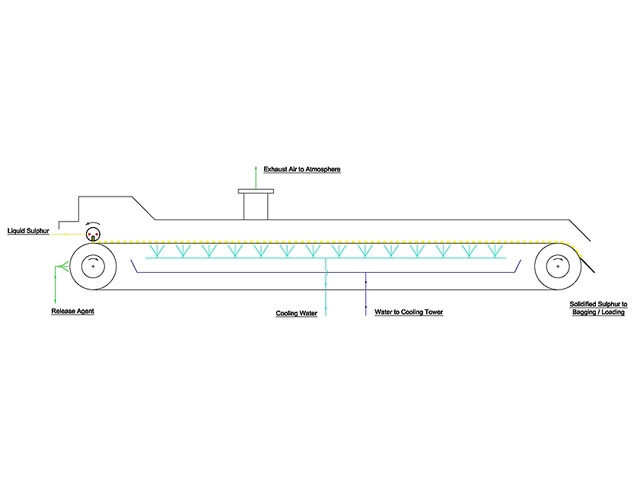

The fusion of the urea and sulphur process in carried out in 4 basic stages:

1. Urea is heated to prepare its surface for sulphur coating.

2. It then enters a rotating drum to be sprayed hydraulically first with sulphur and then with the wax sealant.

3. The product is cooled, coated with diatomaceous earth conditioner to prevent caking.

4. Screened and transferred to storage for testing.

The more nitrogen that is fed to and used by turf, the greater its need for sulphur. Sulphur deficiencies in turf have the same visual signs as nitrogen deficiency; yellowing of leaves, faint scorching of leaf tip. When used in combination with proper ratios of nitrogen, phosphorous and potash, sulphur offers the following benefits:

Using the spouted bed for coating urea with sulphur is efficient and the best quality product is obtained when the bed is maintaining at 80º C. Evaluating the dissolution rate and quality increased at higher sulphur mass flow rates and at lower atomizing air flow rates.

| Shape | Granule |

| Size | smaller than 4-5 mm (Diameter) |

| Color | Yellow |

| Angle of repose | <30° |

| Dust | Less than 1% (wt) |

| Bulk density |

Loose: Greater than 1,050 kg/m³ Agitated: Greater than 1,150 kg/m³ |

| Purity | High purity (as received) |

| Moisture | Less than 0.5% (wt) |

| Others |

Low dust generation during transport Stable chemical and physical forms Low acidity Uniform size and shape |

SCU (Sulphur Coated Urea)