Tar / Pitch / Bitumen Flaker & solidification Package

Pitch / Coal tar / Bitumin flaker and steel belt conveying package is another common method for Flaking, Forming & Solidification unit that has drawn more attention in recent years due to its low impact on the environment for substances with softening point higher than 100 °C. Through Flaker , a thin layer of liquid substance such as sulphur, Pitch, Tar, Urea are placed on a steel belt cooler in regular thickness using a Liquid Pitch or liquid Sulphur feeder Machine. The liquid substances loses heat as it moves on the steel belt cooler and forms into non uniform polygonal shapes called flake.

Since water and liquid substance do not come into direct contact with one another through sulphur/ pitch flake method, flaker entails fewer environmental difficulties than some of other solidification methods. Pitch flake unit is an increasingly popular choice for high softening point pitch /tar due to its relative ease of setup, high quality final product as well as easy storage and transportation in big bag rather than barrel. Another advantage of sulphur / pitch / Coal tar / Bitumin pelletizer unit is its versatility; the same equipment can be used to create other products, such as Urea and a wide range of other substance with high softening point. Some Pitch / Sulphur Flaker, Forming & Solidification plants that use ARIaNA SANAT ZAFARAN CO. steel belt cooler can produce pitch, tar, elemental sulphur, Sulphur Bentonite, urea, or other chemical substances flake according to prevailing market demand. This versatility also accounts for increasing interest in pitch / tar flake unit in production plants around the world.

ARIaNA SANAT ZAFARAN CO. Pitch / Sulfur flaker has an operating capacity of 120 tonnes per day, and their modular design allows them to be integrated together to achieve higher production capacity on demand. This modularity Sulfur / pitch flaker also allows a plant to continue production when one of the units is not operational, while also enabling rapid Sulfur / pitch flaker unit start-up with lower capital investment costs.

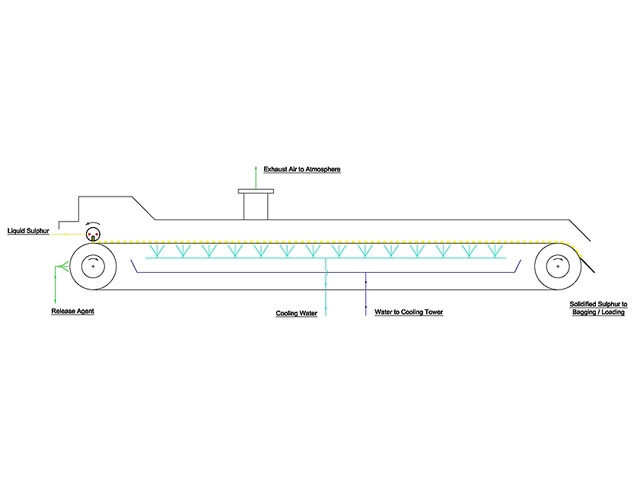

After production pf liquid Pitch / Tar / sulfur in upstream, the liquid substance is transferred to solidification unit and store in a surge drum / buffer tank before it is pumped through a filter into a Sulfur / pitch / tar flaker unit. A Sulfur / pitch flaker consist of two main sections: a feeding bar and a stator . Liquid sulfur / Pitch enters the feeding bar and is injected onto a moving stainless steel belt cooling through the flaker.

Synchronizing of the steel belt cooler speed with the pitch / Tar flaker is one of the most important factors affecting the shape of the flakes and needs to be set precisely at production time of Sulfur / pitch flaker package unit in order to ensure a uniform product shape. When properly synchronized, the injected sulfur / pitch flake form polygonal non uniform shapes as they cool and solidify while moving along the steel belt cooler. The temperature of the steel belt pelletizer is maintained by controlling the temperature and flow rate of water that is sprayed onto the underside of the belt. This water absorbs the heat from the molten substance and then goes to a cooling tower before it is stored in a water tank for re-use at the belt cooler. Based on the climate and temperature of the production plant location, a chiller may be required to supplement the cooling tower. Water never comes into contact with sulphur through this method.

A release agent is applied evenly as a thin layer to the surface of the steel belt cooler to prevent molten substance adhesion, to help removal of the flake from the surface of steel belt cooler, and to ensure a uniform flake shape. The sulfur / pitch flake has an approximate temperature of 60 - 100℃ as they approaches the end of the steel belt cooler based on project specification and requirement,where they are scraped from the belt by a blade , broken by a rotating broker and transported by a conveyor to a storage unit. An exhaust air system installed above the cooling belt prevents the spread of pitch / sulfur gases away from the steel belt cooling pelletizer unit.

| Shape | Flake |

| Size | smaller than 10 cm x 10 cm and 4 mm thickness |

| Color | Black |

| Angle of repose | <30° |

| Dust | Less than 0.4% (wt) |

| Bulk density |

Loose: Greater than 1,050 kg/m³ Agitated: Greater than 1,150 kg/m³ |

| Purity | High purity (as received) |

| Moisture | Less than 0.5% (wt) |

| Others |

Low dust generation during transport Easy to re-melt Stable chemical and physical forms Low acidity Uniform size and shape |

Flake of high softening point pitch

| Capacity | 5 metric tonnes per hour |

| Dimension (mm) |

H: 1,900 W: 2,250 L: 33,000 |

| Weight | 15,500 kg |

| Utility Consumption |

Electric Power: 40kW Steam: 500 kg/h (~250 °C) Water: No net water consumption |

Other Features

- Easy to start up, shut down and operate

- Low maintenance

- Minimal spare part requirements

- Cooling water does not come in contact with pitch

- No air or water pollution associated with flake production

- Method enables water circulation

- Minimal plant footprint

- Allows rapid scaling of plant capacity by integration with additional units

- Flaker versatility also enables the production of high softening point pitch, coal tar pitch, tar, elemental solid sulphur, urea, etc.