National Iranian Oil Engineering & Construction-NIOEC assigned Ehsan Joint Venture as EPC contractor of this project. The EPC Contractor (EHSAN joint venture) consisting of ODCC, IGC, and Design & Inspection Engineering Co. This is the first work experience of our managing team in sulphur solisifcation, handling and storage unit as employee of another company and now we bring these experiences and lesson learned to this company in order to use in similar projects at a higher level of technology and quality.

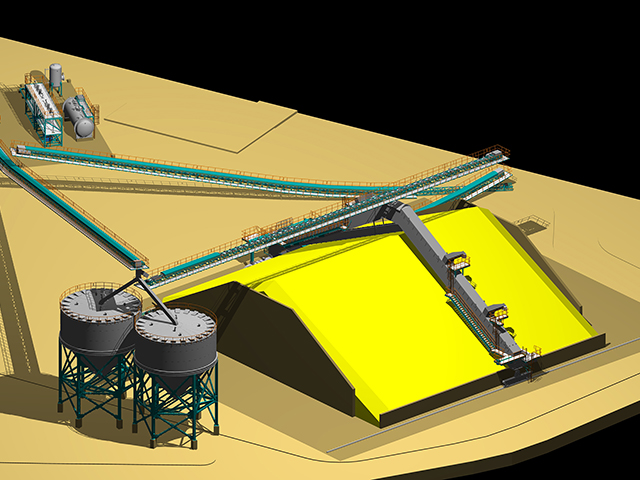

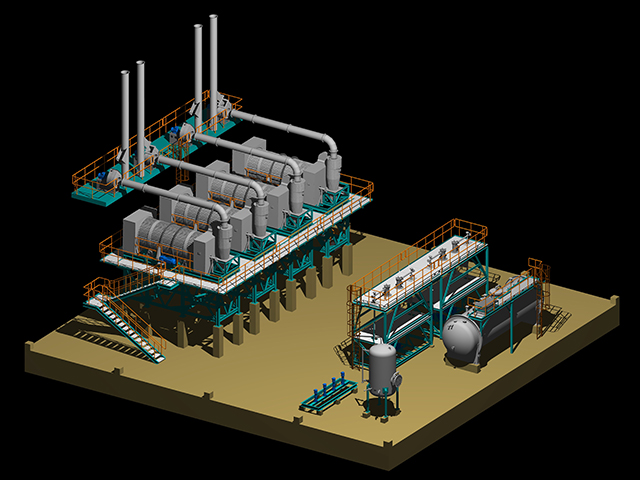

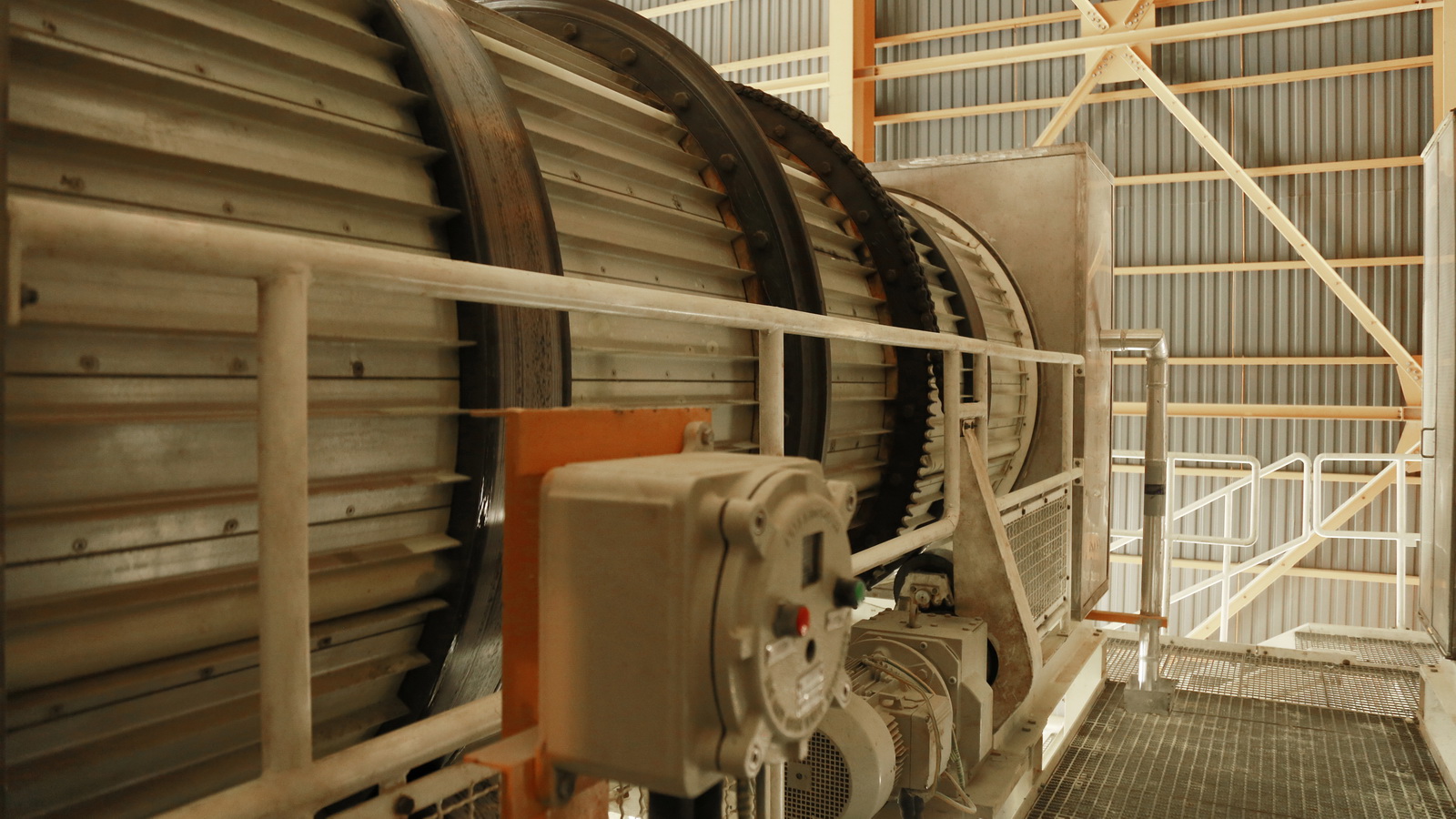

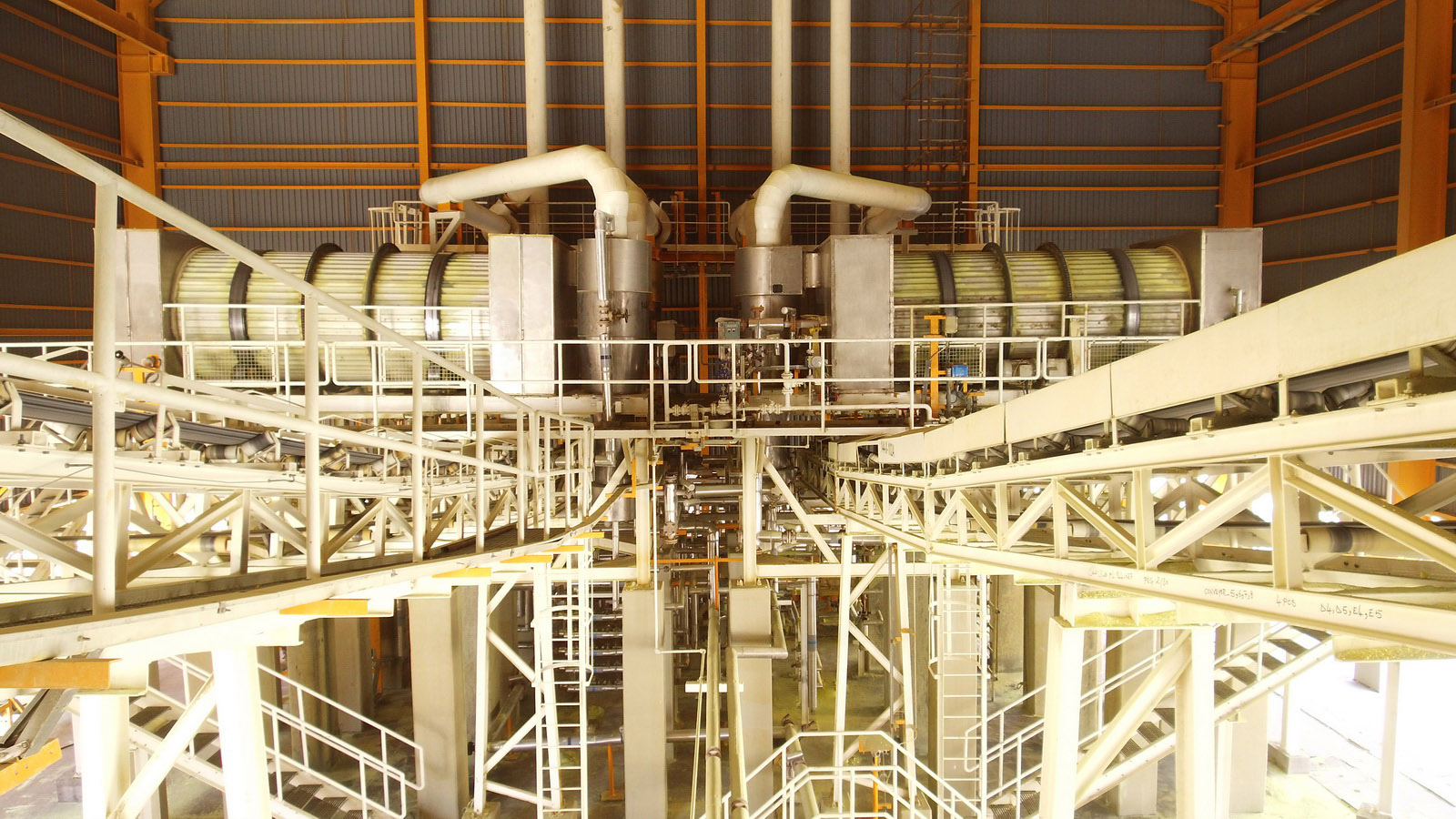

Sulfur / Sulphur Solidification & Forming (Granulation)

and Bulk Material Handling and Storage Unit

| Capacity | 720 tonnes per day |

| Method | Sulfur / Sulphur Granulation |

| Client | Ehsan J.V. (OD&CC, IGC, D&I) |

| Delivery Date | 2011 |

| Status | Completed and in operation |

| Location | Tehran - Iran |

| Feed | Liquid sulphur from SRU plant |

| Product | Granule (spherical shape) Sulfur / Sulphur |

| Number of trains | 2 |

| Train capacity | 15 tonnes per hour / 360 tonnes per day |

| Storage | 2 X 250 tonnes = 500 ton silo |

| Handling | Rubber belt conveyor |

| Equipment |

|